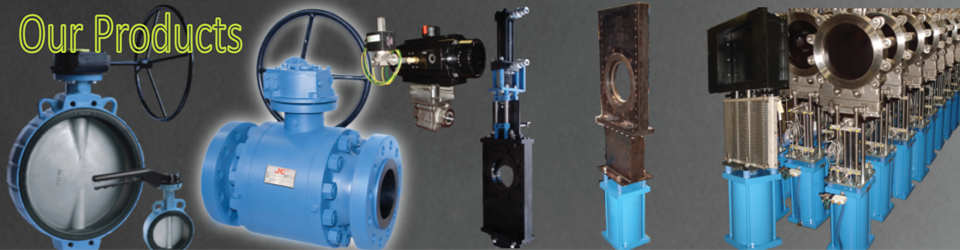

Trueline Products

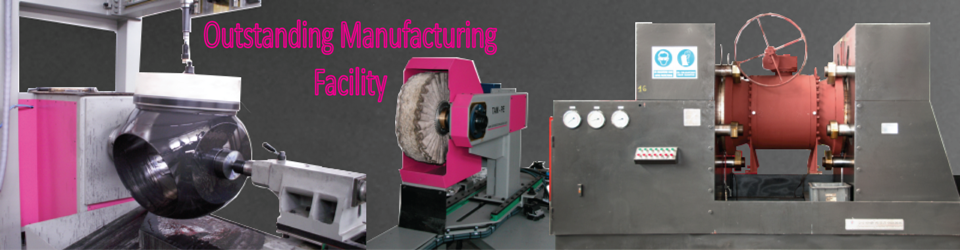

Our proprietary products and vast technical expertise in the valve industry allows Trueline to provide valve solutions for the most severe service applications.

Globe Valve

| Products | Design Features |

|---|---|

SCREWED - L800R |

Globe valve design. Handwheel designed to fit a pipe fitter’s hand; nameplate closely fitted to handwheel hub to avoid cut fingers. Stem thread o.d less than sealing diameter of stuffing box, to avoid damage to packing rings during assembly. Eyebolts mounted on integrally forged bonnet trunions for greater strength, fastened with drive screws for easy replacement if damaged. Stainless steel packing gland, eyebolts and nuts for long life, easy replacement if damaged. Premium Graphoil packing for high pressure/temperature services; other packing available. Premium Graphoil spiral wound gaskets for high pressure/temperature services; other gasket available. Body bonnet joints with spiral wound gaskets for optimum sealing; strong bonnet bolts designed for easy maintenance. Globe plug available in several materials; material clearly marked on plug. Integral globe valve seat stellited for longer service; other materials available. Body ribs to ensure positive grip by pipe fitter’s wrench for screwed valve installations. Oblique and angle pattern valves available. No copper-bearing alloys. No asbestos material in API 602 valves. |

SCREWED - N651 |

Globe valves 3/8" ~ 2" (DN 12~ DN 50). Rising stem. End connections: Threaded end ANSI B1.20.1 (NPT); DIN 259 / DIN 2999; ISO228; BSP; PT. |

FLANGED - N526B (CLASS 300) & N626B (CLASS 600) |

Globe valves 1/2" ~ 6" (DN 15~ DN 150). Valve design according to API 600 BS 1873. Shell wall thickness according to ASME/ANSI B16.34 class 300 and class 600. Pressure – temperature rating according to ASME/ANSI B16.34. Face to face according to ASME/ANSI B16.10 class 300 RF and class 600 RF. End to end according to ASME/ANSI B16.10 class 300 BW and class 600 BW. Flanged dimension according to ASME/ANSI B16.5 class 300 RF and class 600 RF, finish 125-250 AARH. Butt weld dimension according to ASME/ANSI B16.25. |

FLANGED - N116B |

Check valve 1/2" ~ 10" (DN 15~ DN 250). Valve design according to API 600 BS 1873. Shell wall thickness according to ASME/ANSI B16.34 class 150. Pressure – temperature rating according to ASME/ANSI B16.34. Face to face according to ASME/ANSI B16.10 class 150 RF. End to end according to ASME/ANSI B16.10 class 150 BW. Flanged dimension according to ASME/ANSI B16.5 class 150 RF, Finish 125-250 AARH. Butt weld dimension according to ASME/ANSI B16.25. |

Globe Valve Class 150/300/600/900/1500/2500 |

Valve design: ASME B16.34 - BS 1873 - PED - MSS SP-42 |

Globe Valve Class 900/1500/2500 PS |

Valve design: ASME B16.34 - BS 1873 - PED |

© 2020 Copyright Trueline Valve Corporation. All rights are reserved.

About Us| Terms and Conditions| Privacy Policy|

About Us| Terms and Conditions| Privacy Policy|